Sanitary Valves

Sanitary valves are critical components in ensuring safety, quality, and efficiency in hygienic process systems. They play a vital role in controlling fluid flow to minimize the risk of contamination in industries such as food processing and pharmaceuticals.

Ensuring Hygienic Processing with High-Quality Sanitary Valves

Sanitary valves are designed to meet the strict hygiene requirements of these industries. They are made from high-quality materials, such as stainless steel, which is resistant to corrosion and can withstand high temperatures and pressure. Sanitary valves are also designed to be easy to clean, with smooth surfaces that prevent the buildup of bacteria and other contaminants.

At Casellla Process Solutions, we understand the importance of maintaining hygienic conditions in your processing system. That’s why we offer a range of sanitary valve products that are designed to meet the unique needs of your industry. Our team of experts can work with you to select the right valves for your application, ensuring that your production processes run smoothly and your products meet the highest standards of quality and safety.

Connect with a Casella team member to discuss your sanitary valve needs!

Our Products Include:

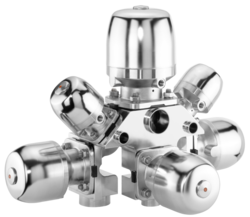

Ball Valves

Multi-Port Valve Blocks

Butterfly Valves

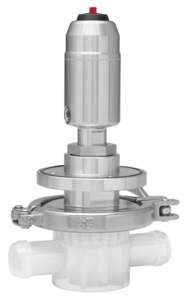

Single-Use Valves

& many more!

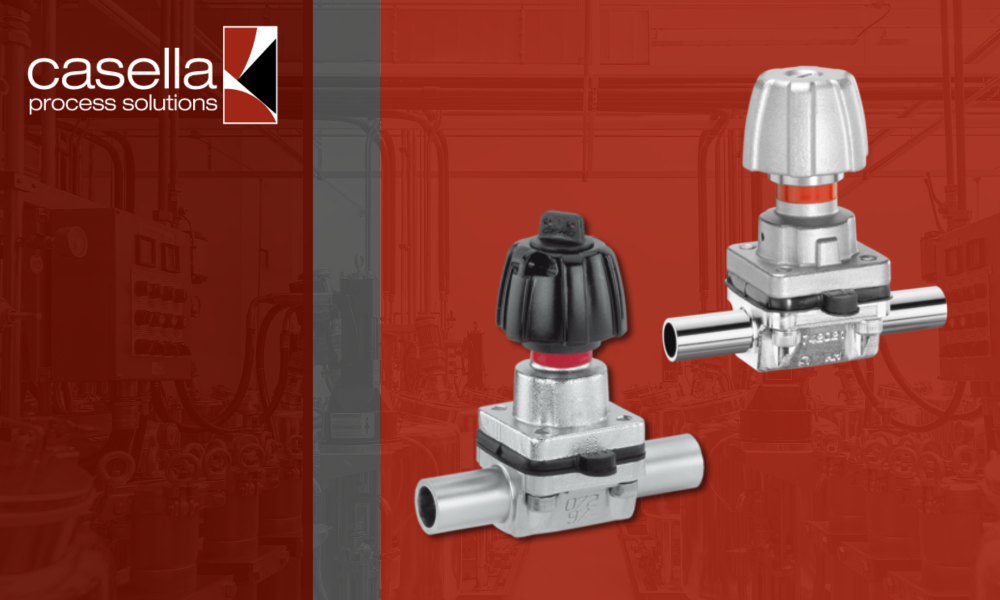

FEATURED

Diaphragm Valves

Sanitary diaphragm valves are an essential component for industries that require strict hygienic conditions. They offer several key features and benefits, including hygienic design, easy cleaning, accurate control, versatility, cost-effectiveness, low maintenance, and durability. These benefits make them an ideal choice for applications in the food and beverage, pharmaceutical, and biotech industries. If you’re looking for a reliable and cost-effective valve solution, consider using sanitary diaphragm valves to improve your product quality and reduce the risk of contamination.

Choosing the Right Sanitary Valve for Your Hygienic Process System

When choosing the appropriate sanitary valve, it is crucial to consider several key factors. These factors include the application, type of fluid, pressure, temperature, and hygiene. It is important to select a valve that not only meets these requirements but also offers ease of cleaning, maintenance, and repair.

Furthermore, the compatibility of the valve body material with the processed fluid should be taken into account. The valve should be able to withstand high pressure and temperature without compromising its integrity.

To guarantee safety, quality, and efficiency in hygienic process systems, it is essential to make the right choice when selecting a sanitary valve. Evaluating factors such as valve type, application, hygiene, and maintenance is crucial to ensure optimal performance while minimizing the risks of contamination.

For example, butterfly valves are suitable for applications requiring high flow rates and frequent cleaning, whereas ball valves offer precise control. Understanding these differences will help you make the best choice for your specific application.

By carefully evaluating these factors and understanding the various types of valves available, you can confidently select the most suitable sanitary valve. This will enable you to maintain safety, quality, and efficiency while minimizing the risks of contamination. When making your decision, you can trust Casella Process Solutions to assist you in choosing the right option for your needs.

Our Trusted Partners

Ensuring Quality and Compliance in Biopharmaceutical Production with Sanitary Diaphragm Valves

Discover how sanitary diaphragm valves play a pivotal role in ensuring quality and compliance in biopharmaceutical production, safeguarding the integrity of processes and meeting rigorous industry standards.

Speak with a Dedicated Casella Representative

Casella has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.