Case Study:

From Frustration to Flow: How a Tri-Clamp Sizer Can Streamline Operations

Tri-clamp fittings are the workhorses of many industries, ensuring secure and sanitary connections in countless applications. But when it comes to sizing, even a seemingly minor mistake can lead to major headaches.

Connect with a Casella Team Member

Case Study: A Critical Contamination

Imagine a pharmaceutical production line bustling with activity, churning out life-saving medication. Suddenly, an alarm sounds, signaling a pressure drop in a critical transfer line. Upon investigation, technicians discover the issue: a seemingly minor leak emanating from a tri-clamp connection. The cause? An ill-fitted component, marginally oversized for the tubing diameter, putting the sterile quality of the entire batch at risk.

This seemingly insignificant error triggers a chain reaction:

- Contamination Risk: The leak exposes the sterile product to potential airborne contaminants, rendering the entire batch unusable. This delays production, impacts patient access to critical medication, and incurs immense financial losses.

- Regulatory Nightmare: Regulatory bodies hold pharmaceutical companies to strict sterility protocols. This breach could trigger extensive investigations, hefty fines, and production halts, potentially damaging the company’s reputation.

- Investigative Delays: Identifying and rectifying the error requires meticulous investigation, further delaying production and impacting patient care.

- Wasted Resources: Replacing the incorrect fitting, disposing of the contaminated batch, and restarting production incurs significant financial losses and setbacks.

While the pharmaceutical plant’s experience may seem isolated, such issues can occur in various industries:

- Reduced Flow: Undersized fittings restrict the flow of critical fluids like buffers and active ingredients, impacting production efficiency and potentially affecting drug consistency.

- Equipment Damage: Mismatched sizes put undue stress on components, leading to leaks, wear and tear, and even equipment failure, disrupting sterile environments.

- Compliance Issues: Regulatory agencies enforce strict guidelines for fitting sizes in pharmaceutical settings. Non-compliance can result in production stoppages and hefty fines.

- Wasted Resources and Delays: Incorrect orders, returns, and rework due to sizing errors lead to unnecessary costs and delays in getting essential medication to patients.

Tri-Clamp Sizer: A Safeguard for Precision

Fortunately, prevention is within reach. Utilizing a dedicated tri-clamp sizer ensures precision by directly measuring the tubing’s inner diameter (ID), the crucial sizing factor. This simple tool guarantees a perfect fit every time, safeguarding against the problems mentioned above.

In the pharmaceutical industry, accuracy isn’t a luxury; it’s a responsibility. Opting for the right tools, like the tri-clamp sizer, ensures safe, efficient production, protects patient health, and safeguards your company’s reputation.

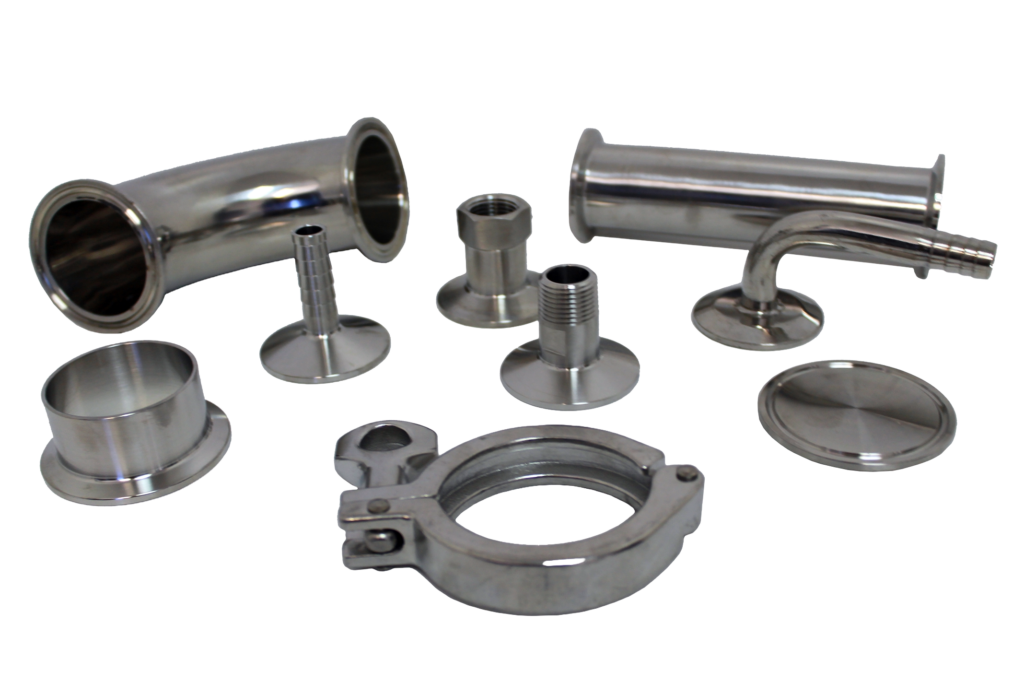

Explore our Tri-Clamp Offering:

Download our FREE tri-clamp sizer now and experience the peace of mind that comes with precise connections.

Ask us how to properly torque your

tri-clamps using the Torque Tee!

Sanitary Clamps

Tri-Clamp Ferrules

Tri-Clamp Caps

Tri-Clamp Elbows

Tees & Crosses

Reducers

Adapters

Gaskets

& Others Available Upon Request

About Us

Thank you for choosing Casella Process Solutions. We specialize in providing technically sophisticated components and equipment for single-use/disposable and traditional stainless steel process applications.

Quick Links

Contact Us

246 Calef Highway, P.O. Box 59

Barrington, NH 03825

Phone: 603.664.7980

Fax: 603.664.7985

Copyright © Casella Process Solutions all rights reserved.