Sanitary Mixers

Sanitary mixers are crucial equipment for industries like food and beverage, pharmaceuticals, and cosmetics, providing efficient and hygienic mixing solutions. These mixers come in different types, sizes, and configurations, and manufacturers can customize them with specialized features to meet specific production needs.

Precision Mixing Solutions for Hygienic Manufacturing

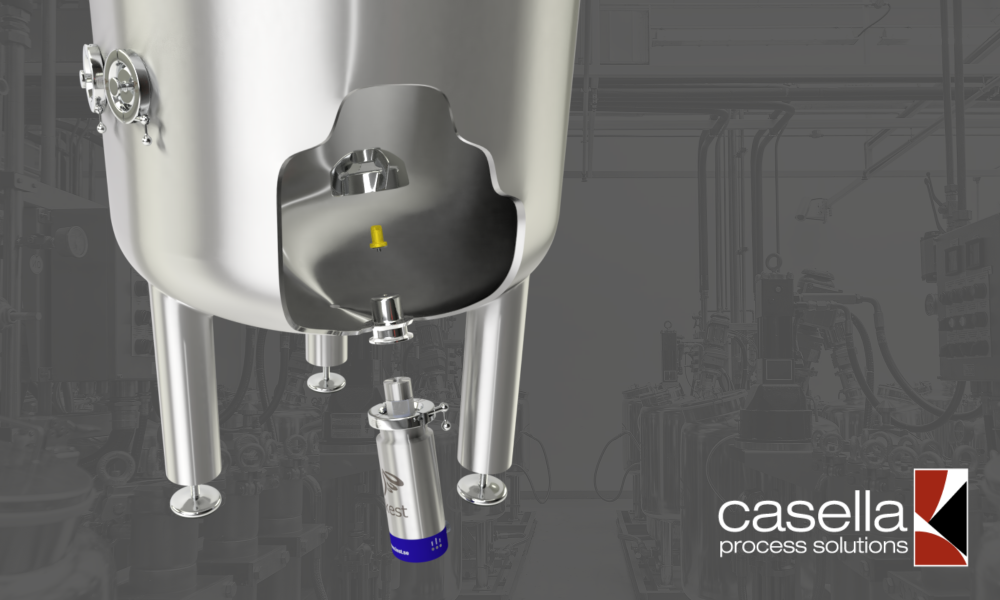

Sanitary mixers are essential for industries that require strict sanitary and hygienic standards, such as food, pharmaceuticals, and cosmetics. These mixers are designed to prevent contamination and ensure product safety by using materials that are corrosion-resistant, non-reactive, and easy to clean.

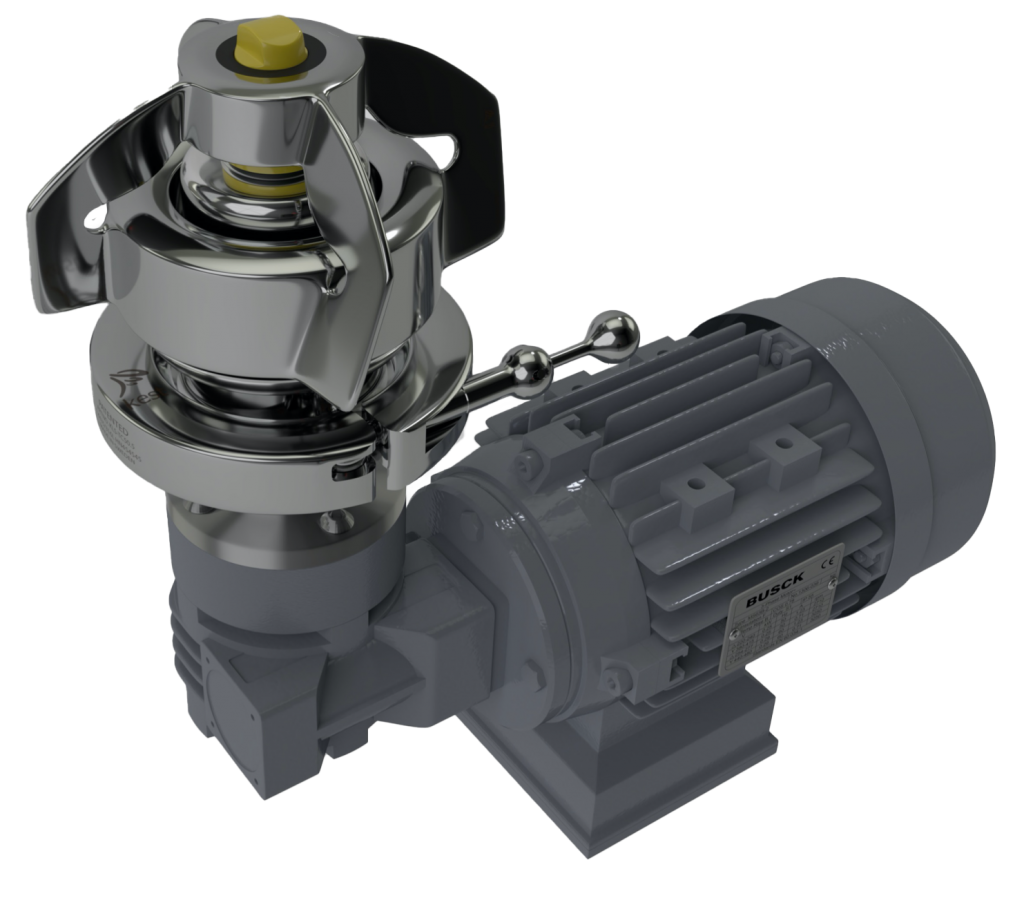

Sanitary mixers have several key features that set them apart from standard mixing machines. They are hygienically designed with smooth, crevice-free surfaces and removable components for easy cleaning and sanitization. They are constructed from materials like stainless steel, which is durable and corrosion-resistant. Sanitary mixers are also capable of delivering high-quality mixing performance, such as blending, emulsifying, homogenizing, or agitating. They come in various designs, including paddle, turbine, and impeller, among others.

Connect with a Casella team member to discuss your sanitary mixing needs!

Our Products Include:

Kest Mixer Rapid Motion – RM

Kest Mixer – KM

ProFlow Mixer – KMPF

Kest Mixer Small Volume – KMS

& many more!

The Importance of Sanitary Mixing

Sanitary mixing plays a crucial role in blending, homogenizing, or agitating materials in a way that meets strict sanitary and hygienic standards. As a result, it is a critical process in the production of food, pharmaceuticals, cosmetics, and other products that require high levels of safety and hygiene. The purpose of sanitary mixing is to produce high-quality, safe, and hygienic products for consumption or use.

Furthermore, using a mixer that meets strict sanitary standards helps prevent the growth of harmful bacteria and other microorganisms that can cause illness or spoilage. Therefore, manufacturers can produce products that are safe, high-quality, and meet regulatory requirements.

When selecting a sanitary mixer, manufacturers must consider several key factors. Firstly, they should select a mixer constructed from materials that are corrosion-resistant, non-reactive, and easy to clean. Secondly, they should opt for a mixer designed to minimize the risk of contamination and that is easy to clean and sanitize. Lastly, the mixer should be capable of delivering the required mixing performance, such as blending, homogenizing, or agitating.

In conclusion, sanitary mixing is a critical process that ensures the safety and quality of products in various industries. By selecting a mixer that meets the material, hygienic design, and performance standards, manufacturers can produce safe and high-quality products that meet regulatory requirements.

Our Trusted Partners

5 Tips for Optimizing Sanitary Mixing Processes for Efficient and Consistent Results

Are you looking for ways to optimize your sanitary mixing processes? Look no further! In this blog post, we’ll share five tips to help you achieve efficient and consistent results in your sanitary mixing processes. From selecting the right mixer to optimizing your mixing parameters, these tips will help you improve your product quality and streamline your production process.

Speak with a Dedicated Casella Representative

Casella has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.