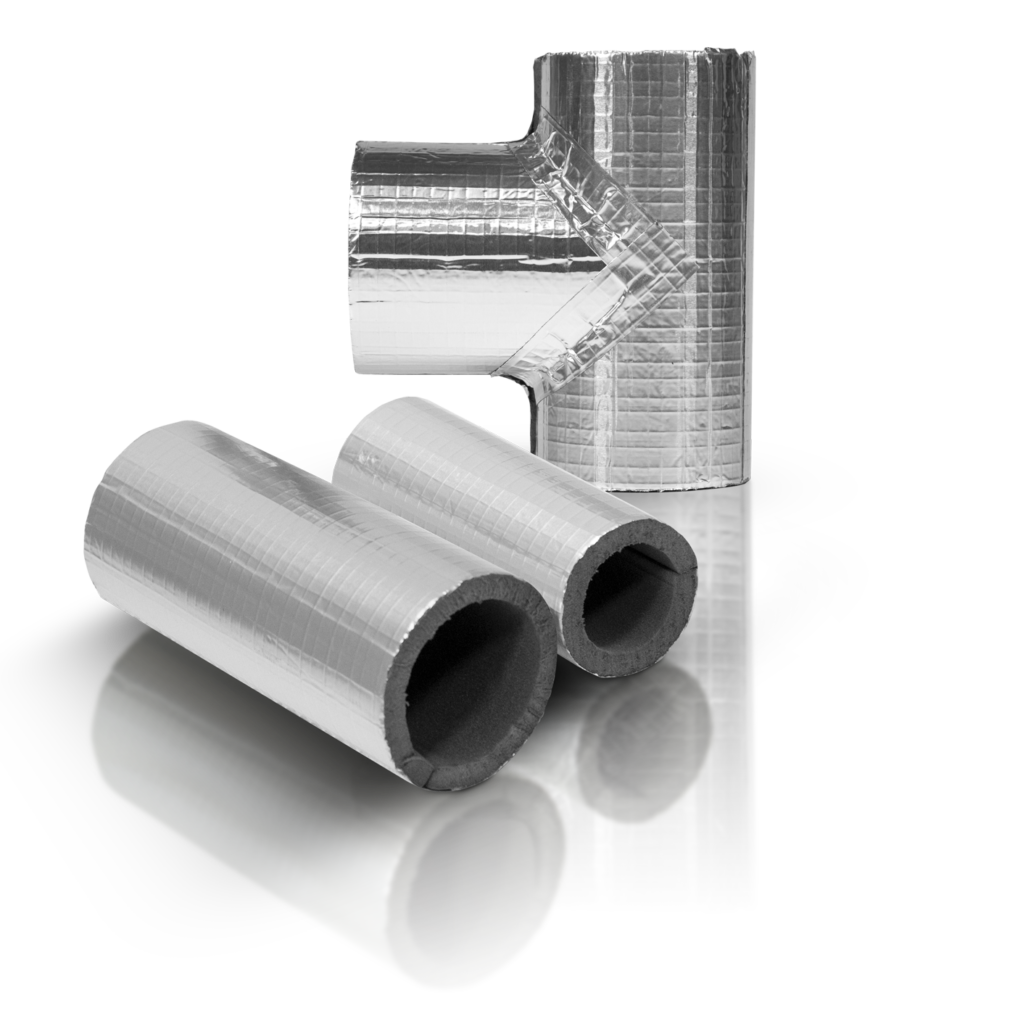

Piping Insulation

Piping insulation is essential for thermal control, condensation prevention, and energy efficiency in various applications, including sanitary processes where materials should be non-absorbent, cleanable, and compliant with sanitary regulations.

Creating a Safe and Sterile Environment with Piping Insulation

Piping insulation is crucial in the pharmaceutical and biotech industries for maintaining the safety and quality of products. Insulation ensures a consistent temperature during production and prevents contamination by providing a barrier between pipes and the surrounding environment. It also helps companies meet regulatory requirements by adding an extra layer of safety and protection. Insulation reduces energy usage by preventing heat loss or gain from pipes and lowers noise levels in the manufacturing facility.

Overall, insulation plays a critical role in the pharmaceutical and biotech industries by maintaining product quality, meeting regulatory requirements, conserving energy, and creating a safe work environment.

Connect with a Casella team member to discuss your piping insulation needs!

Our Products Include:

T-FIT Clean

T-FIT Hygiene

T-FIT Process

When and Where to Use Piping Insulation

Piping insulation is essential in sanitary manufacturing settings to prevent contamination, maintain a sterile environment, and ensure product quality and safety. Here are some examples of when and where piping insulation is commonly used in sanitary manufacturing:

Food and beverage processing: Insulation is used to maintain precise temperature control in food and beverage processing facilities to prevent spoilage and ensure product quality. Insulated pipes also prevent condensation from forming on the surface of the pipes, which can lead to contamination.

Pharmaceutical manufacturing: Insulation is used in pharmaceutical manufacturing to prevent cross-contamination and maintain a sterile environment. Insulated pipes also help to maintain precise temperature control, which is essential for pharmaceutical processes.

Biotech manufacturing: Insulation is used in biotech manufacturing to maintain a sterile environment and prevent contamination. Insulated pipes also help to maintain precise temperature control, which is important for biotech processes.

Dairy processing: Insulation is used in dairy processing facilities to prevent spoilage and ensure product quality. Insulated pipes also help to maintain precise temperature control and prevent condensation.

In sanitary manufacturing settings, the specific type and thickness of insulation used must meet industry standards and regulations for cleanliness and safety. Insulation materials must be non-toxic, non-absorbent, and easy to clean to prevent contamination. In addition, installation of the insulation must be performed using sanitary techniques to prevent contamination during installation.

Our Trusted Partners

5 Key Benefits of Piping Insulation for Energy Efficiency and Cost Savings

If you’re looking to reduce your energy costs and increase your facility’s efficiency, one of the most effective ways to do so is by installing piping insulation. Insulating your pipes offers numerous benefits beyond just reducing heat loss. In this blog, we will explore five key benefits of piping insulation and how it can help you save money and energy in the long run.

Speak with a Dedicated Casella Representative

Casella has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.