Kest Technology

Kest Technology designs and manufactures aseptic fluid handling equipment for the pharmaceutical and food & beverage industries. Their products are used to prevent contamination and to ensure the safety and quality of products in these industries.

Kest Technology

Kest Technology is a global provider of high-quality equipment for aseptic fluid handling. Through our sales network we support the global industry with solutions for agitation, aseptic couplings and sampling systems.

Overview of Kest Mixers

Kest Lock

Kest Lowering Device

Featured Products

New! KM P-Line

Kest Technology introduces the all-new P-Line, a line of magnetically coupled mixers designed specifically for handling highly corrosive media in chemical applications. Made from PP USP Class VI approved plastic, the P-Line offers a robust and cost-effective solution for mixing up to 1200 liters of chemicals.

Key Features of the Kest P-Line Mixers:

- Chemical-Resistant Construction: USP Class VI approved PP plastic ensures exceptional resistance to a wide range of chemicals, making it ideal for harsh environments.

- Magnetic Coupling: Eliminates the need for a shaft seal, preventing leaks and contamination risks commonly associated with traditional mixers.

- CIP (Clean-in-Place) Design: The P-Line’s design facilitates easy cleaning and sterilization, crucial for maintaining hygiene in aseptic applications.

- Interchangeable Tank Plate: The mixing head can be combined with Kest’s stainless steel tank plate for added versatility.

- Multiple Drive Options: Choose from ProFlow DC, ProFlow Remote DC, or KM Remote AC drive units to best suit your specific mixing needs.

Featured Products

Mixers

Kest provides a wide array of durable, precision mixers and tank components for aseptic, reliable pharmaceuticals and food & beverage production.

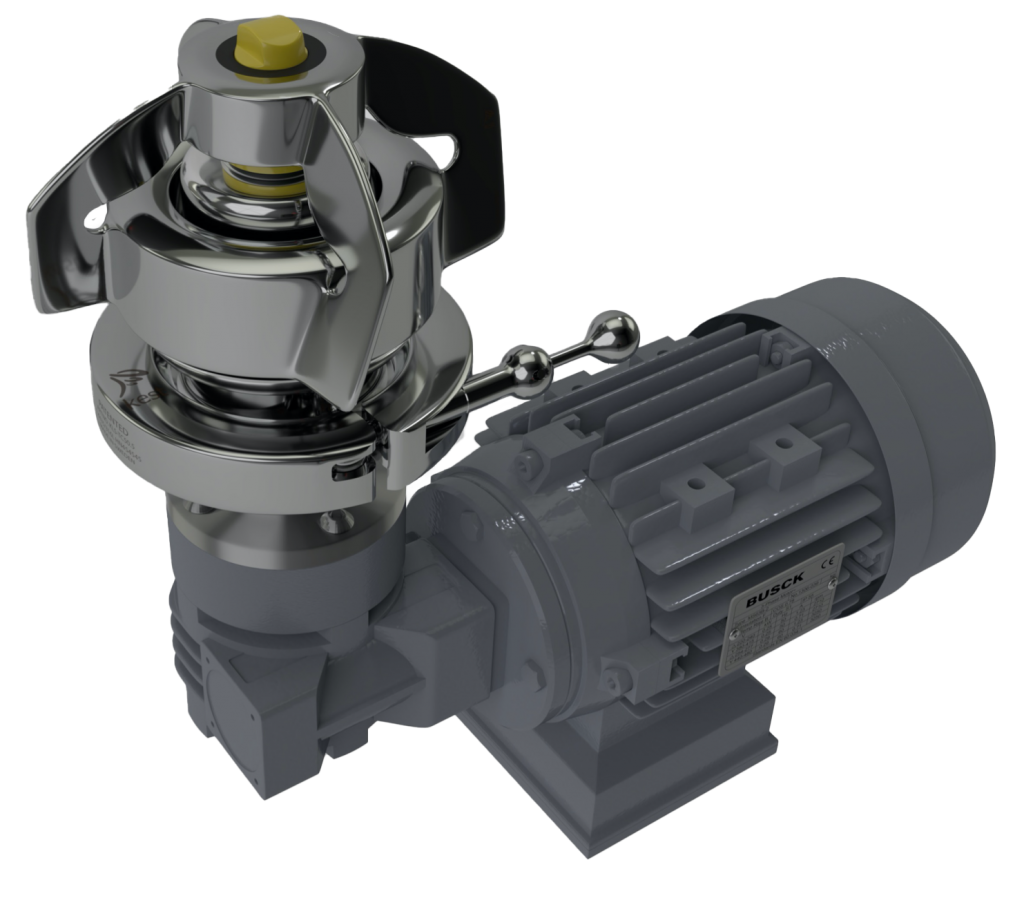

The Kest mixers is a range of magnetic coupled mixers for pharma and aseptic food and beverage applications. The aseptic design is allowing the mixer to be cleaned in place and sterilized in place (CIP/SIP). The tank gets equipped with a tank plate that is welded into the tank, this eliminates any risk of contamination from the outside environment. The placement of the mixer in the bottom of the tank in combination with the bearing design enables for low volume mixing and mixing to the last drop to ensure full product recovery.

Featured Products

Couplings

The Kest-Lock contains one split ring, basic or snap type and one weld-in flange. You place the gasket in the weld-in part and connect your TriClamp device or tube, the snap version will help you to hold the TriClamp device in place while you are tightening the locking device.

The Kest-Lock range contains of several different weld-in parts. Those can also be customized to fit your needs. We can deliver different materials and do custom designs.

Featured Products

Sampling Unit

The Kest Sampling Unit has become a very popular sampling solution, it combines sampling at controlled conditions with cost efficiency and ease of use.

The operator simply penetrates a silicon membrane with a pencil point needle to collect a sample. When removing the needle, the membrane self-seals and can hold a pressure up to 7 bar. The sample can now be extracted from the container to be analyzed. Each sample port can facilitate 8 samples per batch. The system is designed to be fitted to a standard TC- ferrule, ISO 2852. The sample port is easily attached to a tank or pipe with a standard TriClamp connection like Kest-Lock.

The Kest-Lock range contains of several different weld-in parts. Those can also be customized to fit your needs. We can deliver different materials and do custom designs.

Speak with a Dedicated Casella Representative

Casella has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.