Rubber Fab

RubberFab: Trusted Solutions for Every Fluid Handling Challenge

Rubber Fab is a leading manufacturer of sanitary process components, with a focus on gaskets, hoses, and other products used in the food, beverage, pharmaceutical, and biotechnology industries.

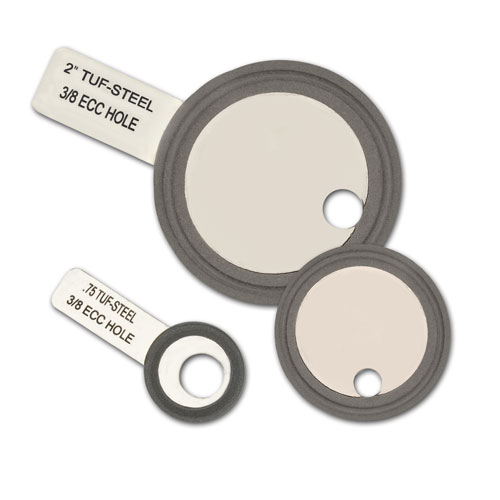

Rubber Fab products are composed of a unique, 50/50 blend of non-pigmented PTFE and 316L stainless steel, steel that is passivated and atomized. Tuf-Steel® is the choice for leak-proof performance and outstanding durability in steam applications.

Connect with a Casella team member to discuss your sanitary component needs!

Products Include:

Gaskets

O-Rings

Sanitary Clamps

Hose Fittings & Adapters

Featured Product

Tuf-Steel®

Composed of a unique 50/50 blend of non-pigmented PTFE and 316L Passivated and atomized Stainless Steel, Tuf-Steel® is the choice for leak-proof performance and outstanding durability in steam applications. The name may have changed from Tef-Steel to Tuf-Steel®, but the gasket, the part numbers and the Rubber Fab quality remains exactly the same.

PTFE and Stainless Steel Tuf-Steel® Offers Rugged Composition for Demanding Steam Environments

Featured Product

Tuf-Flex®

Introducing a technologically advanced new hygienic seal, TUF-FLEX®. This revolutionary new seal from Rubber Fab Technologies Group is the world’s only unitized seal, setting new standards for purity, performance and flexibility. Designed to meet critical requirements in pharmaceutical, biotechnology, ultrapure water, WFI (water-for-injection).

Uniting the flexibility of an elastomer with the chemical resistance of PTFE

The PTFE grafted elastomer in a TUF-FLEX hygienic seal will maintain I.D. without re-torquing or leaking.

Featured Product

Smart Gasket®

Rubber Fab’s Smart Gasket’s® value is proven when validating sterility in a high-purity pharmaceutical system.

Benefits:

Features:

Smart Gasket® with Smart Clamp is available in 1/2″, 3/4″, 1″, 1-1/2″, 2″, 3″ and 4″ sizes and fits standard Tri-Clover®, Top Line®, Waukesha® and G&H® sanitary flanges. Choose between USDA, FDA grade EPDM, platinum-cured silicone, FKM and other elastomers (consult factory for larger sizes).

Rubber Fab’s Smart Gasket® with Spore Trap holder is available with and without a thermocouple port.

Speak with a Dedicated Casella Representative

Casella has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.